Calendar Icon Apr 06, 2022 Person Bust Icon By Emily Case

Making automated farming equipment easier to use and repair is a goal of BSE graduate student Ian Tempelmeyer. This idea led him to win the 2022 Engineering Pitch Competition for the Flex-Ro auto planter concept in March.

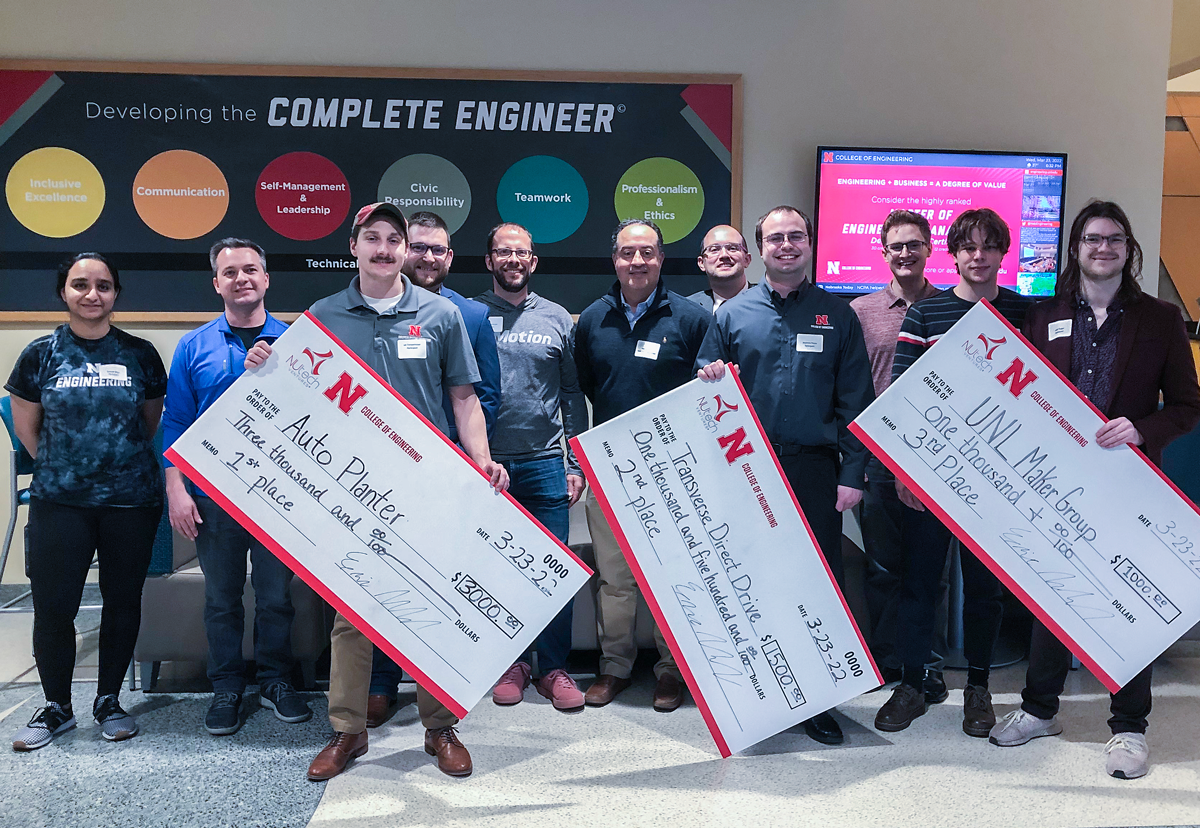

The competition, which is hosted by the College of Engineering and NUtech Ventures, featured teams from various UNL departments. Runner-up projects included a transverse direct drive concept and campus maker group.

Tempelmeyer is in his first year of the Agricultural Engineering graduate program. His focus is on machine automation through agrobotics, or robotic equipment that can be used in the field. He works with his advisor Santosh Pitla, Associate Professor of Advanced Machinery Systems, and others in his lab group to bring the Flex-Ro robot into fields.

“I like what we do and I feel we are making a difference. Our focus is on Flex-Ro and its abilities, and where it can go in the future,” he said.

Flex-Ro, which made a test debut in 2019, can be controlled remotely and operated autonomously. It sits on an adjustable high-clearance platform, weighs about 3,800 pounds and is powered by a gas engine. Each wheel contains an electric and hydraulic motor that can be steered in four different modes, and it uses a hydrostatic transmission.

Tempelmeyer is one of the graduate students who has worked on this project, and the lab group is currently working on adapting it to a variety of field applications. One thing that sets Flex-Ro apart, he said, was that it’s almost entirely comprised of off-the-shelf parts for easy repair combined with intelligent autonomy.

“There’s not a lot of custom manufacturing so if a farmer needs to fix it, he has the ability to do that — not relying on a dealership to find parts,” Tempelmeyer said.

Pitla agreed, saying Flex-Ro is easy to repair and maintain despite its advanced autonomy features.

“This makes it a very producer-friendly robotic platform that can work long hours in the field and amplify what producers can do in the field,” he said. “You can think of it as a high-tech farmhand that is modular and multi-purpose.”

Tempelmeyer learned about the pitch competition after trying to get Flex-Ro patented with NUTech. While the office is still considering whether to pursue patent or not due to insufficient data, they encouraged him to enter the concept in the competition to help it gain traction.

Winning was the last thing he envisioned as he prepared his pitch.

“I was the last person to apply and it was maybe two weeks (before the competition) to throw something together, so it was a lot of late nights scrambling,” he said.

Ultimately, the experience helped him see the project through a different lens. As he discussed the pitch with NUTech staff over office hours they offered, he developed a compelling argument for Flex-Ro.

“It seemed the thing that made us shine was that I focused on the business aspect. Who is the market, why would they use this tech, why would it be beneficial now,” he said. “We highlighted that cover crops are gaining traction and people are realizing how important it is to diversify the crops you plant.”

Moving forward, his group plans to use the $3,000 prize money to continue testing and expand Flex-Ro’s features. Some ideas include adding a larger tank to plant for longer periods of time and hiring a third party to test planting efficiency for a variety of seeds.

Tempelmeyer, who is from Lincoln, said a background in mechanics is what shaped his graduate school focus. He wants to bridge the gap between engineers and technicians.

“I was a diesel mechanic for the army before I came (to the grad program),” he said. “When I got into school I decided I wanted to design machinery. I faced a lot of issues with the way things were designed and it was irritating. … I want to make things easier for people.”